Process Controls

The Flexibility You Want, with Safety and Reliability You Need

LCT’s controls packages offer the enormous level of functionality desired by process engineers, while allowing them to be simplified at the operator level for ease of use. Linton’s controls can measure hundreds of variables and have multiple modes of controlling the main process, such as by power or temperature, and closed loop (feedback based) or open loop (recipe based) control.

Additionally, all LCT controls have a minimum of two safeties, often combining redundant hardware and software switches to maintain a high level of safety that conforms to the most rigid of plant conditions.

Key Features

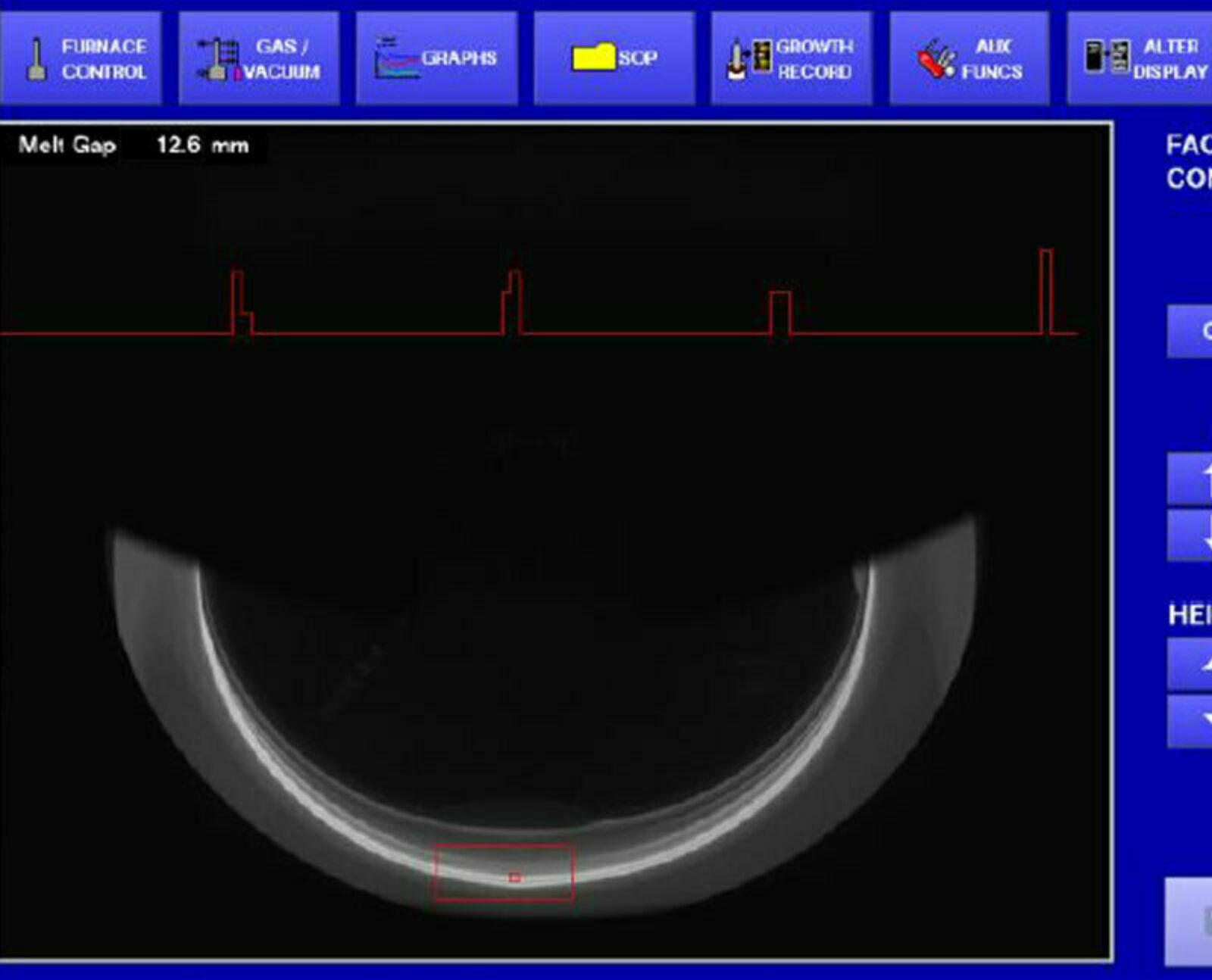

Melt Gap

An automated melt gap measurement system compares real-time crystal visuals with calculations to ensure accuracy and safety.

Facet Detection

Facet detection software uses vision and AI methods to determine when structure loss occurs and, with a composite of the two methods, virtually eliminates any false positive alarm. This allows the operator to stay focused and productive in his tasks instead of responding to non-issues.

Remote Control Interfaces

Also available are remote control interfaces, allowing customers to design their own controls while leaving the machine OS intact. This keeps them eligible for software upgrades while allowing them to customize their controls privately.

Kayex Upgrades

For those with older Kayex systems, there are KICCS upgrades to bring their old machines up to current control standards. This allows them to take advantage of all the enhancements LCT offers.

Future Enhancements

Linton’s coming control enhancements include melt/freeze detection, stabilization and automatic recharge processes. These will shorten the amount of time operators and process engineers spend observing the machines so they can spend more time on other tasks and keep the machine productive.

Retrofit Controls

If you have one of our older systems running on DOS platforms or early KICCS, we offer affordable upgrades to the controls packages to allow you to keep running your old furnaces and get the maximum production from them until you are ready to buy a new, larger furnace.